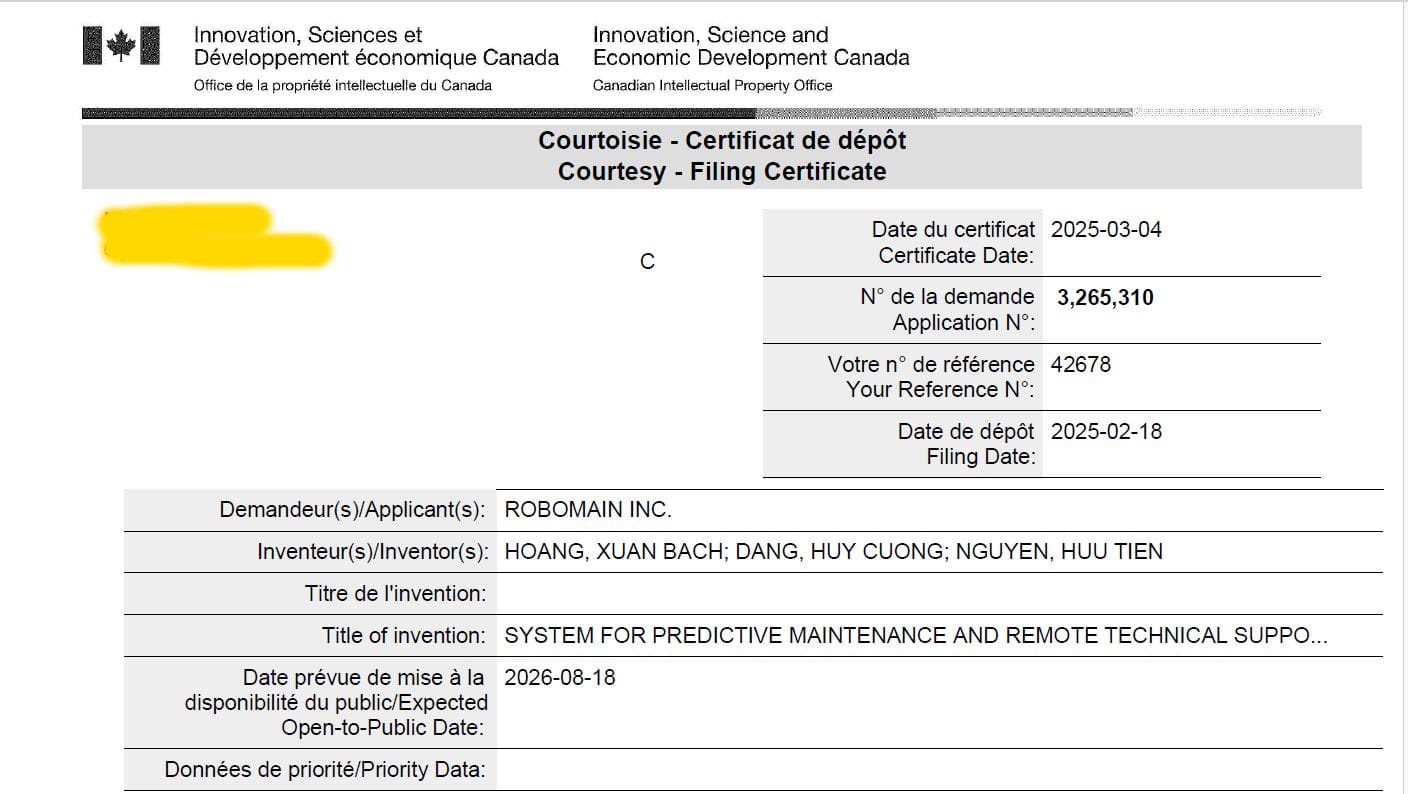

Romain successfully filed a patent application and received a certificate on February 18, 2025 for the invention of a SMART Industrial Maintenance Management and Remote Support System. This innovative system integrates advanced technologies, including artificial intelligence (AI), Industrial Internet of Things (IIoT), and Edge AI computing, to optimize predictive maintenance, enable remote technical support, and streamline troubleshooting.

Addressing Challenges in Industrial Maintenance

Industrial facilities, such as manufacturing plants, energy hubs, and logistics centers, face persistent challenges like unplanned downtime, inefficient maintenance scheduling, and reliance on on-site expertise. These issues can lead to significant financial losses, with unplanned downtime costing manufacturers up to $50 billion annually. Robomain’s SMART system tackles these problems by combining real-time monitoring, AI-driven analytics, and remote support capabilities. Filing a patent is a critical step to protect this intellectual property, ensuring Robomain’s competitive edge in the smart manufacturing market, projected to reach USD 658.4 billion by 2029.

Key Features of the SMART System

The SMART system is designed to enhance maintenance efficiency and minimize operational disruptions through a suite of advanced features. Below are the nine patented features that define its innovation:

Seamless Smart Technology Integration for Predictive Maintenance and Remote Support

The system integrates AI, IIoT, and Edge AI computing to deliver predictive maintenance and instant troubleshooting. By connecting sensors, cloud platforms, and AI algorithms, it enables proactive identification of equipment issues and real-time remote support, reducing downtime.Edge AI as a Multifunctional Hub

The system’s Industrial AI Computers operate as Edge AI, Sensor Hub, and KVM (Keyboard, Video, Mouse). This multifunctionality allows localized data processing, sensor management, and remote equipment access, enhancing operational flexibility in factories.KVM for Remote Expert Access

As a KVM system, the SMART platform enables suppliers’ technical experts and customer support teams to remotely access factory computers and equipment. This facilitates maintenance and troubleshooting without the need for on-site visits, reducing response times and travel costs.Edge AI Data Collection for CMMS

Edge AI collects real-time data on equipment status via serial ports, intranet, or sensor networks and transmits it to the Computerized Maintenance Management System (CMMS). This ensures comprehensive data aggregation for analysis, enabling precise maintenance decisions.AI and IIoT-Powered CMMS

The CMMS leverages AI and IIoT to monitor manufacturing equipment and production lines in real-time. By analyzing metrics like vibration, temperature, and pressure, it provides actionable insights into equipment health, reducing unexpected failures.Localized Decision-Making with Edge AI

Certain data processing and decision-making tasks occur at the Edge AI level without requiring CMMS involvement. This reduces latency, enabling rapid responses to anomalies, such as adjusting machine settings to prevent failures.Real-Time Technician Communication

Factory technicians can engage in remote sessions with technical managers and experts through the SMART system. This feature supports collaborative troubleshooting and maintenance, improving repair accuracy and efficiency.Data Storage and Analysis in CMMS

All interactions between technicians and technical managers are stored in the CMMS for later analysis. This historical data enhances predictive models, improves maintenance strategies, and ensures compliance with industry standards.AI-Driven Anomaly Detection and Predictive Maintenance

AI algorithms in both Edge AI and CMMS analyze data from multiple sources (sensors, logs, and historical records) to detect anomalies and predict maintenance needs. This proactive approach can reduce downtime and maintenance costs.

Industry Impact

The SMART system addresses critical industry pain points, such as equipment downtime and reliance on on-site expertise. By integrating predictive maintenance, remote support, and real-time analytics, it offers tangible benefits:

Reduced Downtime: Predictive maintenance and Edge AI analytics can cut unplanned downtime, boosting productivity.

Cost Efficiency: Automated workflows and optimized scheduling reduce maintenance costs.

Scalability: The cloud-based architecture supports facilities of all sizes, from small plants to global enterprises.

Compliance: Secure data storage and audit trails ensure adherence to regulations like ISO 27001 and FDA 21 CFR Part 11.

Robomain’s SMART Industrial Maintenance Management and Remote Support System is a game-changer for industrial operations, combining AI, IIoT, and Edge computing to deliver predictive maintenance, remote support, and instant troubleshooting. Its nine innovative features—from seamless technology integration to AI-driven anomaly detection—set a new standard for Maintenance 4.0. Filing a patent is the final step to protect this cutting-edge system, ensuring Robomain’s leadership in the smart manufacturing revolution. As industries worldwide adopt these technologies, the SMART system is poised to drive efficiency, reduce costs, and transform maintenance practices for years to come.